- Thank you received: 0

140a and 106 Austin A90 Atlantic (1951-58)

4 years 6 months ago #23282

by DavidT

Replied by DavidT on topic 140a and 106 Austin A90 Atlantic (1951-58)

A few simple questions. 1. Do we know how many moulds were made for each model at the same time, was it just one or numerious? 2. How many castings were expected out of each mould? 3. Each time a mould was replaced the newly made would likely try to eliminate any problems incurred previously or include any potential cost savings. The question then if numious moulds for each casting, it is possible as moulds would not necessaryly be replaced at the same time that different finishes for each model could be being cast at the same time. Alterations to existing moulds ie engraving would always result in additional metal, see the road roller 'Moto-cart' changed to 'Motocart', the digging out the mould to form the cartouche correcting an earlier mistake. David

Please Log in or Create an account to join the conversation.

- dinkycollect

-

- Offline

- User

-

Less

More

- Thank you received: 0

4 years 6 months ago #23283

by dinkycollect

Replied by dinkycollect on topic 140a and 106 Austin A90 Atlantic (1951-58)

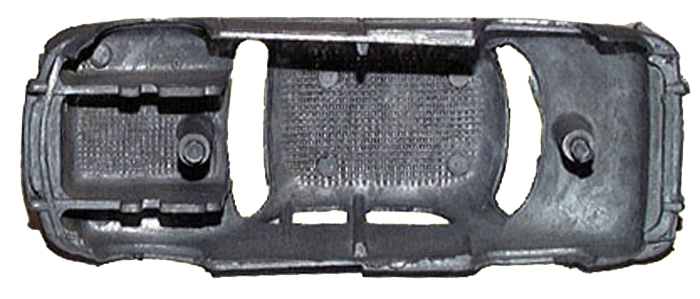

Dear Terry and David In a post above, I probably did not explain enough when I wrote that cross-hatching was to reduce the quantity of metal. This is because the alternative to cross-hatching was to make that area thicker.Three is no information about how many moulds were made for each model but ther was usually one only. There is evidence that parts of a mould had been replaced (24u Simca Aronde) and that two moulds were made one after the other (521 Bedford artic) a third case is that two complete moulds were made at the same time ( Bedfords TK or 33 Simca Cargo) because the planed production figures were high. Such moulds vere never identical and several variations can be found between them. Raised lines like those on the roof of the 28e Isobloc coach, the roof of the 811 caravan or the tipper of the 585 Berliet GAK end tipper are other means of mastering the metal flow in the moulds. Cross-hatching is not done only on the ceiling of cars but also under the bonnet or boot.

24 E - Renault DauphineThere is almost no information on how many models were cast in each mould but the figure is certainly above 1/2 a milion. Only a few models may have reach such a production figure so only one mould was made.

24 Q - Ford Vedette 1951As stated on page 24 of the April 1954 issue of the French Meccano Magazine 500 000 models had been made when this model was withdrawn

24 N - Citron 11 BL said big fifteenThe' Meccano Actualits' news letter informs us that the Citron 11cv is the first Dinky Toys (French or French + English ?) to have been made at more then 1 000 000 units. We do not know if this means the car with a boot or both models. Moulds were never engraved. They were first machine tooled (raised door lines) and in Liverpool from 1960 made by spark erosion (recessed door lines). Yes, any alteration of a moulds results in more metal been needed for each casting. It is extremeny difficult to do the oposite : any change made by adding metal to the mould.Jacques

Please Log in or Create an account to join the conversation.

4 years 6 months ago #23284

by DavidT

Replied by DavidT on topic 140a and 106 Austin A90 Atlantic (1951-58)

Can see I used the wrong word 'engraving', for any alteration of any mould. Just been reconciling the maths to put the quantiy into some sort of perspective for me to comprehend. Assuming 24 /7 production, which am sure was not the case,1,000,000 models, using one mould would be 19230 models for a 7 day week, 2747 models per 24hour day, 114 models per hour, or just under 2 models per miniute for each mould. Obviously some models were in production much longer than one year and also there was probably a six day per week or even a five day. It is also unlikely that there was production for each 24 hour. It just puts the numbers into perspective the amount of work each mould would need to do. Question, would a mould need to rest between each pour because of the heat or can a mould work continiously for long periods. Would imagine it is the same today as it was then. David

Please Log in or Create an account to join the conversation.

4 years 6 months ago #23285

by DavidT

Replied by DavidT on topic 140a and 106 Austin A90 Atlantic (1951-58)

Is it the general understanding then that each variation of a casting replaced the a worn out predessor or was it just an addition to the cast ability, hence cross overs in time ie two slightly modified castings in production at the same time. David

Please Log in or Create an account to join the conversation.

- dinkycollect

-

- Offline

- User

-

Less

More

- Thank you received: 0

4 years 6 months ago #23286

by dinkycollect

Replied by dinkycollect on topic 140a and 106 Austin A90 Atlantic (1951-58)

More figures from the September 1954 issue of the French Meccano Magazine, I doubt that any more exist. 24 N - Big fifteen 550 000 after 4 years of production but there were 3 more years to go. The total production figure is over 1 000 000. 24 R - Peugeot 203 450 000 after 4 years of production but there were 5 more years to go 24 T - 2 cv 490 000 after 4 years of production but there were 9 more years to go 24 U - Aronde 260 000 after 1 1/4 years of production but there was 1 more year to goDo not calculate the total production for each of these models, it can not work because a huge initial run was made before the date of issue so that every shop in the world gets at least one trade box of 6. From this the production figures were reduced until the minimum economic figure was reached, it is then not economical to launch a new run and the model is deleted from the catalogue.

Please Log in or Create an account to join the conversation.

- dinkycollect

-

- Offline

- User

-

Less

More

- Thank you received: 0

4 years 6 months ago #23287

by dinkycollect

Replied by dinkycollect on topic 140a and 106 Austin A90 Atlantic (1951-58)

David, I am not sure that I understand your question in # 28.

photo by courtesy of Bruce HoyIf a mould is modified, there is no going back but of course there are unassembled parts in the store which will be mixed at random with the new modified parts making hybrid models like this Euclid / Terex truck which has a Terex grille and a Euclid chassis.If I did not answer your question, let me know. Jacques

Please Log in or Create an account to join the conversation.

4 years 6 months ago #23290

by DavidT

Replied by DavidT on topic 140a and 106 Austin A90 Atlantic (1951-58)

You certainly have extensive knowlodge and it is really interesting, you must have read every Meccano Magazine and retained all that information, brilliant. Its little bits of information like this that puts perspective on the production. You have certainly answered my questions Thank you David

Please Log in or Create an account to join the conversation.

- dinkycollect

-

- Offline

- User

-

Less

More

- Thank you received: 0

4 years 6 months ago #23291

by dinkycollect

Replied by dinkycollect on topic 140a and 106 Austin A90 Atlantic (1951-58)

David, Your USB stick has been posted yesterday. I wish you a good reading Jacques

Please Log in or Create an account to join the conversation.

4 years 6 months ago #23292

by DavidT

Replied by DavidT on topic 140a and 106 Austin A90 Atlantic (1951-58)

Look forward to being educated. Off to Stafford toy fair this Sunday will be with James Marshall on his stall when not looking, and John Knox. Going to buy some poor quality models that do have variations under the casting to strip down to be kept as naked examples of differernt casting or that's my intention, plus looking for some trade boxes. David

Please Log in or Create an account to join the conversation.

- dinkycollect

-

- Offline

- User

-

Less

More

- Thank you received: 0

4 years 5 months ago #23288

by dinkycollect

Replied by dinkycollect on topic 140a and 106 Austin A90 Atlantic (1951-58)

David, Moulds can run permanently 24 hours a day, they do in some factories but not at Meccano. They are heated electrically and by the injection of molten metal which itself is re-heated by compression through the small injection nozel.There are two official production figures for the Bobigny factory which was much smaller than Liverpool. 1951 - 7 000 000 Dinky were made that year using 600 ton of zamac and 26 000 000 tyres 1956 - 12 000 Dinky were made every day The Meccano Magazine of September 1954 contains an article about the manufacturing of Dinky Toys which states that the output of the factory was of 24 Dinky every minute. Of course this meant different models been made at the same time. No mould could run at such a rate. The article also says that the rate of a mould was 5 - 7 castings a minute meaning a model every ten seconds.Jacques

Please Log in or Create an account to join the conversation.

4 years 5 months ago #23328

by MUMBY655

Replied by MUMBY655 on topic 140a and 106 Austin A90 Atlantic (1951-58)

Regarding the subject of cross hatching on the underside of Dinky roofs and sometimes bonnets and boots. Prior to the mid 1960's the steel of diecast tools manufactured at Binns Road was not hardened. Over time the abrasive flow of Mazak damaged the top surface of the core that produces the inside of the models. This damage was sometimes called 'die soldering'. Rather than replace the core or totally remachine the damaged surface which would take time it was discovered by experiment that cross hatching disguised the damage and added less Mazak. During opreration it is the core of the tool that runs the hotest. After discussion with tool steel manufacturers the steel quality of tools was changed and the tools were fully hardened. Tool life was now extended considerably and the need for cross hatching eliminated. An example of longevity is DT104 SPV the body tool of which produced approaching 250,000 shots before it had to replaced due to demand for the toy. Meccano used Zinc Alloy type Mazak 3 which melts around 400C. During operation a diecast tool is water cooled to allow solidification of the Mazak after injection. Consequently the tool is subject to cyclical heating and cooling. This produces the effect of 'heat checking' which the steel quality has to resist and finally fails by crazing appearing on the die surfaces. This caused the premature failure of the Avro Vulcan tool cast in Aluminium. The unhardened tool could not withstand the Aluminium at 600 plus degrees C. Hope this helps with the discussion. Vic Mumby (former Chief Draughtsman for products and tooling at Meccano Ltd)

Please Log in or Create an account to join the conversation.

- binnsboy650

-

- Offline

- User

-

Less

More

- Thank you received: 0

4 years 5 months ago #23335

by binnsboy650

Replied by binnsboy650 on topic 140a and 106 Austin A90 Atlantic (1951-58)

Thank you Vic, that's fascinating information. I don't think the technical side of things is uppermost in many collectors' minds but a little understanding makes things much more interesting. John

Please Log in or Create an account to join the conversation.

Time to create page: 0.502 seconds