- Thank you received: 0

Dinky Toys manufacturing.

- dinkycollect

-

Topic Author

Topic Author

- Offline

- User

-

Less

More

11 years 1 month ago #5783

by dinkycollect

Dinky Toys manufacturing. was created by dinkycollect

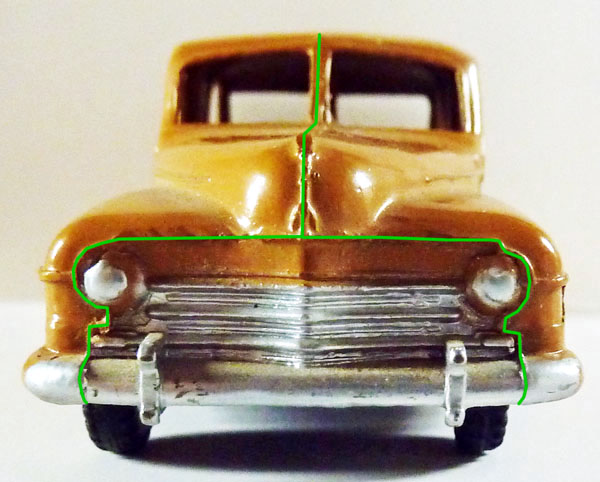

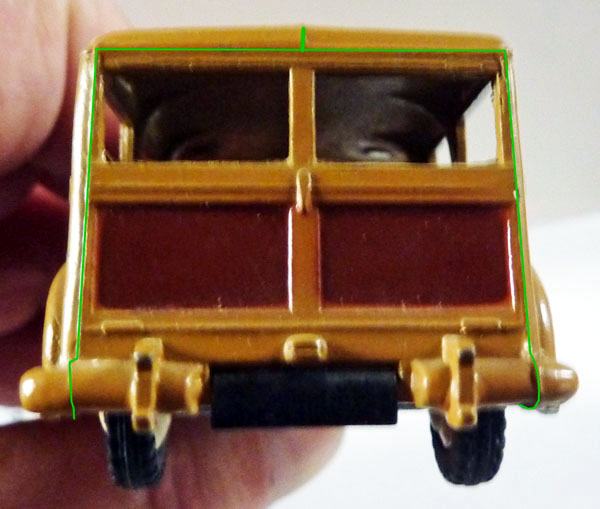

This post has been transfered from the thread 'Matching pictures).I believe I have shown this photo once before. I used it as a demonstration that possibly a more or less squarish model was a bit easier to cast, allowing for a seam of the vertical halves in the middle.

The models on top are square and show that seam. The models below have more round shapes, which took more die- elements to cast in my opinion. So possibly, if there was an opportunity to make a more square model, the casting would be easier - and cheaper no doubt. Just a theory ....Kind regards,Jan

Please Log in or Create an account to join the conversation.

- dinkycollect

-

Topic Author

Topic Author

- Offline

- User

-

Less

More

- Thank you received: 0

5 years 8 months ago #15785

by dinkycollect

Replied by dinkycollect on topic Dinky Toys manufacturing.

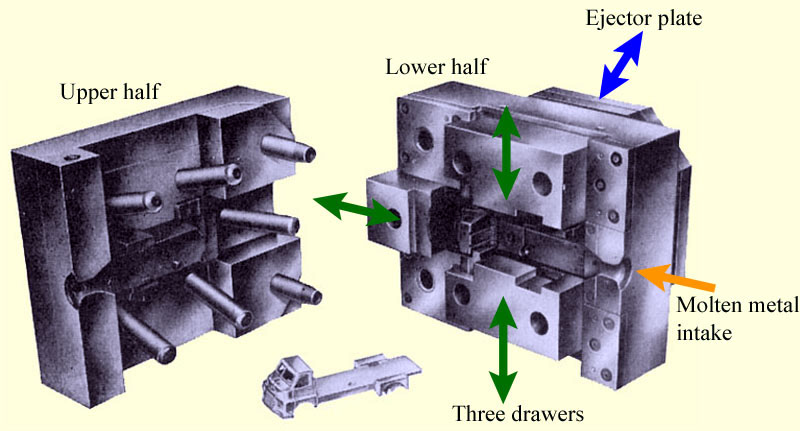

This is the die for the Big Bedford chassis and cab. It shows how things work.When designing a die, one must take in account the shape of the casting to be made and where to hide the seems or die partition lines. In the case of the Plymouth, the Daimler ambulance and others, the seem are clearly visible on the roof but it is hiden in the center line of the bonnet.The die for these models with vertical rear have four sliding drawers. The Big Bedford has two only. On the picture above, you can see that these drawers are square, they have a very tight fit with the other parts ofthe die so that there is no flash in between.Jan is right, the rear of the Plymouth has been made square because otherwise the mobile part of the die on which the rear hatch is machined would have had a curved top which is probably possible but extremely difficult to make.I am sorry but it is difficult for me to explain all this in English and in writing. If you wish, I could explain this verbally during the next AGM.

Partition lines for 27f Estate car.

Please Log in or Create an account to join the conversation.

- dinkycollect

-

Topic Author

Topic Author

- Offline

- User

-

Less

More

- Thank you received: 0

5 years 8 months ago #22282

by dinkycollect

Replied by dinkycollect on topic Dinky Toys manufacturing.

Raised versus recessed door lines. This discussion has started else where but I shall try to explain what I know about this subject. Early Dinky Toys had raised door lines which do not comply with real vehicles. At that time (1933 - 1954) the moulds where cut by milling machines and these lines were easyer to do than recessed lines. The mould was first made smooth without lines, later the lines were ground.

Electrode for the Solido Peugeot D4 van Then comes the new technology of spark erosion. Instead of copying a large scale wooden or resin master a solid copper sample of the model was used as an electrode which was used to cut the mould. The door lines were cut into the electrode and of course the mould had the lines inverted which means raised. In turn the casting had inverted lines from the mould and the finished product had recessed lines. Raised details like door handles, bonnet emblem and the like were still milled into the mould. You have not understood, never mind give me a call and I will explain further. The first Dinky Toys with recessed lines is certainly the Austin Atlantic issued in 1951. The die for this model has probably been sub contracted as at that time Meccano almost certainly did not have a spark erosion facility.

The next model was the 24v Buick Roadmaster issued in January 1954. Bobigny did not make it's own moulds, they were all subcontracted to specialised companies who had up to date equipement. Next came the 24y Studebaker Commander issued fourteen months later in June 1955 and the 24x Simca Versailles in March 1956.

Liverpool issued their first two recessed lines cars in January 1961 seven years after the Buick Roadmaster. These were the 195 Jaguar 3,4 l and the 185 Alfa Romeo Super Sprint but of course, this was a French casting. Next came the 186 Mercedes 220 SE, the 949 Wayne School bus in February 1961 followed by the 194 Bentley (which is not a coupe) in March 1961 and from then all the new models.

A caracteristic of these first English dinky, mainly the Jaguar and the Mercedes is their extremely light weight. The seven year delay for introducing spark erosion in Binns Road may be partly due to the unions which at the time were reluctant to any new technology which of course used less labour. It is known that when the electrostatic painting line was installed, it took months before it was used thanks to the unions who discussed who would work on it, at which salary, with which bonus and all that fuss. No wander the company packed up.

Please Log in or Create an account to join the conversation.

- Jan Oldenhuis

-

- Offline

- User

-

Less

More

- Thank you received: 0

5 years 8 months ago #22297

by Jan Oldenhuis

Replied by Jan Oldenhuis on topic Dinky Toys manufacturing.

Jacques, thank you very much for your clear technical explanation. It is very valuable that you provide this technical explanation. It makes understanding the making of the model with its lines so much more valuable. I am very happy with this kind of information from you with explanations and images in the forum and hope to enjoy your contributions much more.Kind regards, Jan Oldenhuis

Please Log in or Create an account to join the conversation.

- dinkycollect

-

Topic Author

Topic Author

- Offline

- User

-

Less

More

- Thank you received: 0

3 years 11 months ago #23621

by dinkycollect

Replied by dinkycollect on topic Dinky Toys manufacturing.

This is a question for Vic Mumby.Dear Vic, For a long time, I have wanted to know how the marking was done on the castings. Which technique was used ? Thanks for your help.Jacques

Please Log in or Create an account to join the conversation.

3 years 10 months ago #23641

by MUMBY655

Replied by MUMBY655 on topic Dinky Toys manufacturing.

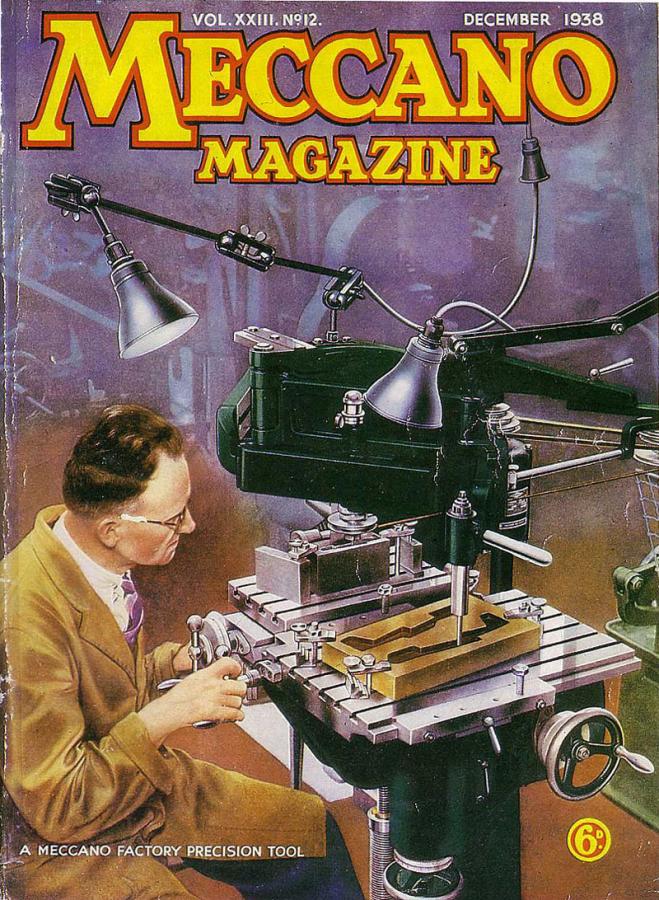

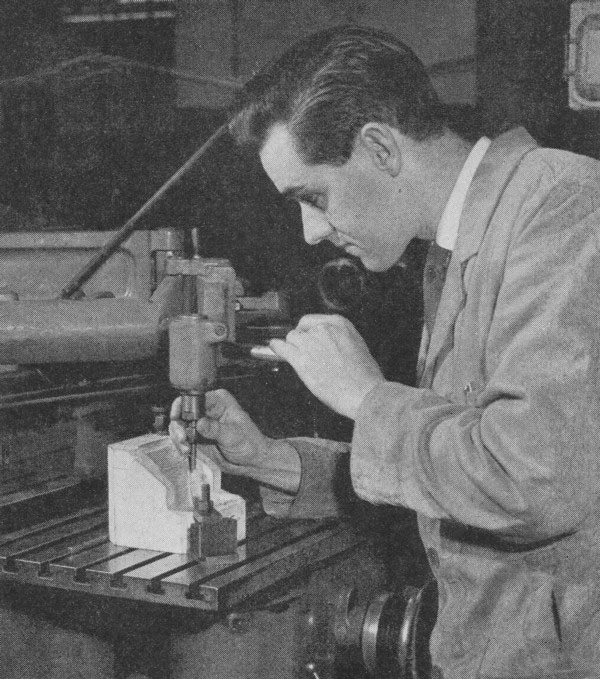

Hello Jacques, I assume you mean the model number, Meccano Ltd, Made in England etc? The letters were machined into the plastic or diecast mould using a Pantograph reducing (copying) machine. On one side of the machine would be female large scale letters and numbers in reverse. The toolmaker would guide a stylus over the letters or numbers and a fine cutter on the other side of the machine would engrave the letters into the steel of the mould. The Pantograph would be set to apply the appropriate reduction in size from the masters to the mould. The engraving is female in the mould and in reverse so the finished product becomes male and reads correctly. Hope this helps. Kind regards Vic Mumby

Please Log in or Create an account to join the conversation.

- dinkycollect

-

Topic Author

Topic Author

- Offline

- User

-

Less

More

- Thank you received: 0

3 years 10 months ago #23648

by dinkycollect

Replied by dinkycollect on topic Dinky Toys manufacturing.

Thank you Vic for this information. Kind regards.

Please Log in or Create an account to join the conversation.

- dinkycollect

-

Topic Author

Topic Author

- Offline

- User

-

Less

More

- Thank you received: 0

3 years 10 months ago #23649

by dinkycollect

Replied by dinkycollect on topic Dinky Toys manufacturing.

Please Log in or Create an account to join the conversation.

3 years 9 months ago #23654

by MUMBY655

Replied by MUMBY655 on topic Dinky Toys manufacturing.

Hello Jacques and Jan, I would like to add some comment on your prevoius discussion about raised or sunken detail door/bonnet/boot lines. When I started my toolmaking apprenticeship at Binns Road in 1961 all body castings were being produced with sunken lines, although with the eventual introduction of opening doors etc, sunken lines were needed less. This was achieved without EDM (Spark Erosion). Binns Road did not get it's first EDM machine until Mid '60's and it was used for other more intricate purposes than car body tooling. The late aquisition of the EDM machine had nothing at all to do with union resistance; in fact the toolmakers at Binns Road were only to pleased to have any new technology. Meccano was one of the first companies to install 3 of the newly developed Bridgeport Universal Milling Machines during the '60's. Anyway, getting back to the sunken detail lines. These were achieved by carving them into the 3 or 4 times full scale wooden patterns. Developments in superior casting resins mean't that the female castings taken from the wooden pattern were very robust and resist any damage when the stylus of the Pantograph machine was traced over them and came into contact with the raised detail that produced the sunken lines in the finished product. Meccano also used specialist toolmakers especially in the 70's when Binns Road had insufficient capacity to meet the very busy Dinky product program which at that time was to release TWO models per month. These toolmakers had access to very high quality pattern makers. These subcontracted patterns would be submitted to the Drawing Office at Binns Road for approval before die cutting could commence. Toolmaking has always facinated me and during the whole of my working career I have been able to follow and utilise the technological advances as they occured. Vic

Please Log in or Create an account to join the conversation.

3 years 9 months ago #23655

by janwerner

Replied by janwerner on topic Dinky Toys manufacturing.

Please Log in or Create an account to join the conversation.

3 years 9 months ago #23656

by MUMBY655

Replied by MUMBY655 on topic Dinky Toys manufacturing.

Hello Jan, I cannot offer a definate explanation as to why the Austin Atlantic has sunken lines. The model was introduced in 1951 when EDM machining was in it's infancy/being developed and certainly not at Binns Road. The only logical possibility I can offer is that the lines were produced as I have previously described as an experiment; but the effort of trying to do the copying on the pantograph without breaking the fragile raised lines on the early castings taken from the wooden pattern was very time consuming and the idea abandoned until superior casting resins appeared. My elder brother (now 90 years old) was a toolmaker at Meccano during the time of manufacture and introduction of the Austin Atlantic. He may recall some facts about the car. I will ask him about it. Vic

Please Log in or Create an account to join the conversation.

- Jan Oldenhuis

-

- Offline

- User

-

Less

More

- Thank you received: 0

3 years 9 months ago #23657

by Jan Oldenhuis

Replied by Jan Oldenhuis on topic Dinky Toys manufacturing.

Did Meccano Liverpool perhaps use resin as diecast metal for model 195 Jaguar 3.4 liter saloon (August 1960 - with recessed lines)? When I got the model I was amazed at the light weight of the model. It weighs 52 grams. For example, the Model 176 Austin A105 (April1958 - with raised lines) is heavier and weighs 86 grams. The body of the 195 is much thinner than that of the 176. Was another diecast metal used at the same time as the erosion spark technique? From a cost saving standpoint I would think that using thinner metal saves production costs? Jan Oldenhuis 8 April 2022

Please Log in or Create an account to join the conversation.

Time to create page: 0.541 seconds